sheet metal rib 29 Gauge thickness, 36-in panel coverage and 3/4-in rib height with major ribs on 9-in on center. Unique bell-shaped rib design gives it added strength. Perfect for roof and wall applications with a variety of uses, minimum recommended roof .

An explosion-proof junction box is a specialized enclosure designed to safeguard electrical connections in hazardous environments. These junction boxes are engineered to .

0 · sheet metal strengthening ribs

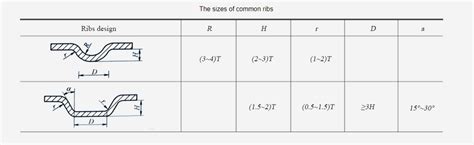

1 · sheet metal stiffening rib design

2 · sheet metal stiffening rib

3 · sheet metal rib design guidelines

4 · sheet metal design guideline pdf

5 · how to stiffen sheet metal

6 · hemmed edge sheet metal

7 · classic rib metal roofing panel

Heavy Structural Fabrication: An Overview. What Is Heavy Structural Fabrication? Heavy structural fabrication is the process of manufacturing large and complex structures from metal components, often involving the assembly of beams, .

A common way to add strength to a sheet metal part is to add strengthening ribs. As the material is deformed, the effective material thickness increases, strengthening the material. Two ways .Mate has two ways to add strengthening ribs: Mate’s Rollerball™ tool and a .The Mate Rollerball™ tool creates stiffening ribs and decorative beads in sheet metal .Classic Rib® Install Guide. The application and detail drawings in this manual are strictly for illustration purposes and may not be appli-cable to all building designs or product installations. .

Mate has two ways to add strengthening ribs: Mate’s Rollerball™ tool and a beaded emboss tool. Mate’s Rollerball tool allows fabricators to reduce sheet metal thickness .29 Gauge thickness, 36-in panel coverage and 3/4-in rib height with major ribs on 9-in on center. Unique bell-shaped rib design gives it added strength. Perfect for roof and wall applications with a variety of uses, minimum recommended roof .

The tool forms the sheet metal by “pinching” the material between two ball bearings in the upper assembly and one ball bearing in the lower assembly. Doing so creates the stiffening rib that can be used to strengthen the sheet metal. The shape of the form is the result of programs created in the punch press programming system.

Description: Panels: The T-Rib panel shall have a width of 12″, 14″, 16″, or 18″ wide. Seams shall be 2½” high with a ½” top flange angled at 90 degrees to the seam to facilitate the seaming of the panel and cap.Get free shipping on qualified 3' Wide Rib Panel Metal Roofing products or Buy Online Pick Up in Store today in the Building Materials Department.Sheet Metal: Simulation: SimulationXpress: Sketching: SLDXML Data Exchange: SOLIDWORKS Sustainability: Tolerancing: TolAnalyst: . Glossary: Creating Ribs. To create a rib: Sketch the contour to use as the rib feature on a plane that intersects the part, or is parallel or at an angle to an existing plane. Click Rib (Features toolbar) or Insert . The Mate Rollerball™ tool creates stiffening ribs and decorative beads in sheet metal parts without a secondary operation. It is available in popular tool st.

Download scientific diagram | Rib sizes (measures in millimetres, above) and ribbing process (below) from publication: Sheet metal plate design: A structured approach to product optimization in .6 Metal Sales Manufacturing Corporation / Subject to change without notice / Effective 8/19 CLASSIC RIB®} Finishes: MS Colorfast45®, ColorFit40™, Versa20 and Acrylic Coated Galvalume®} Corrosion Protection: AZ55 per ASTM A 792 for unpainted Galvalume® AZ50 per ASTM A 792 for painted Galvalume® AZ35 per ASTM A 792 for painted Galvalume® .Max-Rib is a low profile (3/4") panel that is equally well suited for residential roofing and post frame applications. . Mega Rib Panels, Multi-V Panels, Multi-Cor Panels, R Panels, Flat Sheet Metal, Meridian Roofing, Meridian Panels, MCP Panels, Cool Roofing, Energy Efficient Roofing, Standing Seam Roofing, Easy Bolt Prefabricated Steel .The industry-leading Monarch Rib panel provides customers with longevity they can depend on for years to come. These panels are an economical solution that allows your customers to keep their project budgets in check. Our Monarch Rib panels are a popular choice in the agricultural and post-frame industries.

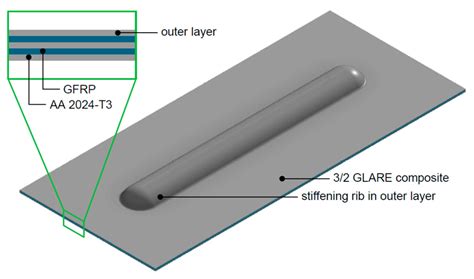

The flat sheet metal part is not strong enough, as it lacks of the structural integrity. In addition, the flat sheet metal part is easy to bend and deform under pressure. Therefore, the flat sheet metal design should be avoided. Adding ribs, flanges, or hems to sheet metal parts are suggested to bolster the sheet metal parts.

Essentially, a rib is a flat, protruding structure added to a sheet metal part, usually on its bottom or inside surface. These structures provide extra strength and robustness to the part, while also preventing unwanted deformation or warping.How Ribs On A Sheet Of Metal Deck Are Made: A sheet of metal decking is cold rolled into the desired profile shape, which determines the size and shape of the ribs. Why Ribs On Metal Deck Matter: The Ribs on a specific sheet of decking gives the steel decking its unique profile. Learn more about The Anatomy of Metal Deck.Metal Rib Part No. SBMETALRIB Sheet Size 27” x 97” Surface/sheet 18 sq ft Pallet/Ordering 250 pcs / 4500 sq ft Rib Space 3.80 Overlap 2” at overlap Tie Wire Spacing 6” Spacing (20” Height) 24” at 210 psf Sheet Thickness 26 Gauge Weight per sq.ft 0.66 lbs Weight per sheet 11.9 lbsThe symmetrical design of McElroy’s Mini-Rib exposed fastener panel make it an appealing profile for walls, soffit, liner and fascia applications. . Mega Rib Panels, Multi-V Panels, Multi-Cor Panels, R Panels, Flat Sheet Metal, Meridian Roofing, Meridian Panels, MCP Panels, Cool Roofing, Energy Efficient Roofing, Standing Seam Roofing, Easy .

Our 5 Rib metal panel holds up against industry safety standards as the choice option for the commercial and residential market. Regardless of whether your roofing project is a new install or a re-roof, or whether it’s commercial, .The expanded metal sheets are easy to cut, lap, splice, bend and pierce, minimizing related forming costs. When concrete is placed, the ribs and mesh are embedded in the structure, providing a rough surface for subsequent concrete . Low Rib Panel – our most cost-effective metal roofing profile – is visually appealing, durable, and energy efficient. This product is mostly used for carports, shelter applications, post-frame, and residential roofing. . “Pioneer Metals will meet all your sheet metal needs. The sales department is a pleasure to work with.Stiffening Rib Mode: Forms the sheet metal to create a rib that can be used to stiffen the sheet metal to reduce sheet flex. This is particularly helpful in large unsupported panels. Allows fabricator to reduce sheet metal thickness without compromising the strength and rigidity of the product; Eliminates secondary brake press or welding .

Applications: Roof Coverage Width: 36" Rib Height : 5/8" Panel Attachment : Exposed Fastening System Gauge : 29 and 26 Coatings : Galvalume Plus®, Signature® 200 Finish Type : Siliconized Polyester Related Industries: Agricultural, Post-FrameThe rugged polyester finish will stand up to the harshest weather conditions and is backed by a 40-year warranty. SM-Rib is an exposed fastener panel. Panels are secured to the roof deck with color-matched gasketed screws to prevent leaking. SM-Rib panels are easily cut with shears and being light weight makes them easy to use and transport.

DESIGNING SHEET METAL PARTS: BEST PRACTICES TIPS AND TRICKS FROM THE SHOP FLOOR. . RIB Entire section must be restrained flat while forming with custom tooling. DESIGN TIPS • Close proximity form features can cause secondary operations after forming and adds to manufacturing cost.

I'm having trouble putting a rib into a sheet metal part for strength. I would like to put it in along the 90 deg bend in the middle about a 1/4 inch deep. Not sure how to go about doing it.

Delta Rib™ metal roofing and siding is a light gauge, exposed fastener panel is ideal for residential, light commercial, agriculture, retail, and civic projects.This versatile panel offers architects, homeowners, and building owners new choices.

Deep Rib II Metal Panels for Roofing Applications: The Deep Rib II panel shall have a coverage of 30″ for steel and 40″ for aluminum”. Rib height shall be 2″. Panels shall be directly fastened to the substrate. The panel shall have a overlapping side-lap feature. Product Brochure – Full GuideFor example, 4″ Box Rib wall panels are frequently used in power plant lagging, and 4″ . Compare this product Remove from comparison tool. corrugated sheet metal LP 20 DK. ribbed steel for facade cladding. . Secure partition, this exceptionally strong galvanised metal sheet provides protection against determined attack with hand or .

Tex-Rib is a low profile (3/4") panel that is well suited for commercial, agricultural and residential applications. Tex-Rib can be installed on as low as a 1:12 pitch if sealant is used on the sidelaps. . Contact Form; Products Metal Roofing Metal Components Metal .

custom cnc watch parts

sheet metal strengthening ribs

sheet metal stiffening rib design

Today the Lathes are commonly used in industries such as automotive, oil & gas, aerospace, medical, mining, power plant, electronics, and shipbuilding. Simple CNC lathes or CNC turning machines are operated with .

sheet metal rib|sheet metal design guideline pdf